Ifanele amanethiwekhi wamandla njengeziteshi zikagesi.Ukufakwa emiseleni, ngaphansi nangaphandle.Sicela uqaphele: Igobolondo langaphandle elibomvu lingaba lula ukufiphala lapho lichayeke emisebeni ye-UV.

Amazinga:

Ukusabalalisa ilangabi ku-BS EN60332

BS6622

I-IEC 60502

Izici :

Izintambo zethu ziziqhayisa ngezici ezilandelayo ezivelele:

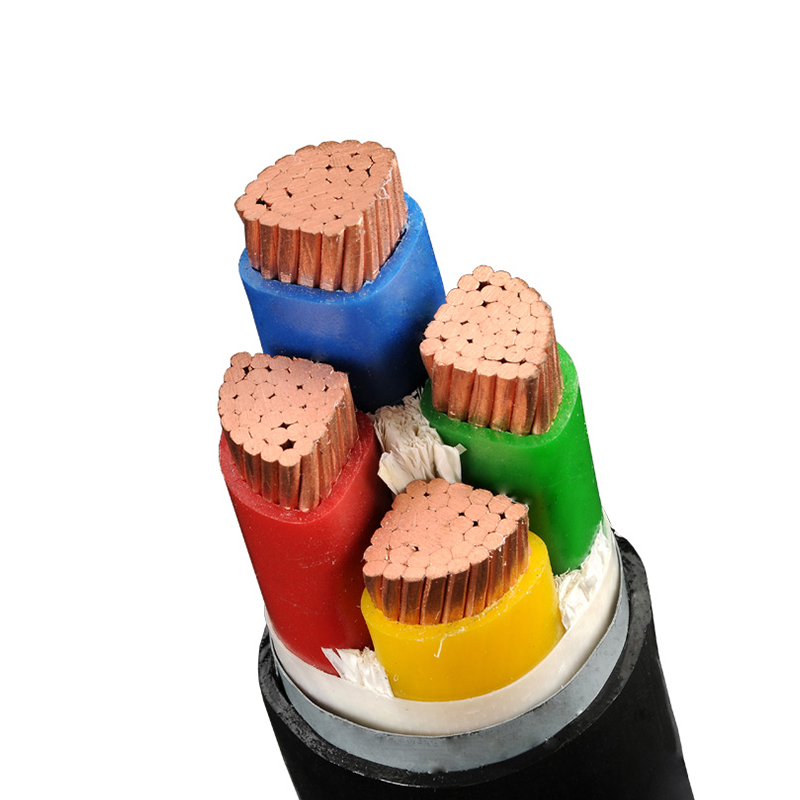

I-Conductor: Amakhondaktha ethusi ahlanganisiwe ayindilinga ahlanganisiwe angenalutho nomaumqhubi we-aluminium.

I-Insulation: Kusetshenziswa i-polyethylene exhunywe ngokuphambana (XLPE) ekusebenzeni okukhethekile.

Isikrini se-Metallic: Inketho yesikrini se-copper tape ngayinye noma sisonke, ukuvikela okuthuthukisiwe.

Isihlukanisi: Itheyiphu yethusi enokweqa okungu-10%, iqinisekisa ubuqotho bekhebula eliphakeme.

Indawo yokulala: I-Polyvinyl chloride (PVC) yokuqina okwengeziwe.

Izikhali: Khetha kusukela ku-Steel Wire Armor (SWA), Steel Tape Armor (STA), Aluminium Wire Armor (AWA), noma i-Aluminium Tape Armor (ATA) ngokusekelwe kuzimfuneko zakho ezithile.

I-Sheath: Ifakwe umgodla wangaphandle we-PVC oqinile, ohlinzeka ngokuvikeleka okwengeziwe.

Umbala We-Sheath: Utholakala Ngobomvu noma Omnyama, ubhekelela okuncamelayo kobuhle.

Idatha kagesi:

Izinga lokushisa eliphezulu lokusebenzisa ikhondatha: 90°C

Izinga lokushisa eliphezulu lokusebenza kwesikrini: 80°C

Izinga lokushisa eliphezulu le-conductor ngesikhathi se-SC: 250°C

Izimo zokubeka ekubunjweni kwe-trefoil zimi kanje:

Ukumelana nokushisa komhlabathi: 120˚C.Cm/Watt

Ukujula kokungcwaba: 0.5m

Izinga lokushisa eliphansi: 15°C

Izinga lokushisa lomoya: 25°C

Imvamisa: 50Hz

3.8/6.6kV-Single core copper conductor XLPE insulated yethusi tape ehlolwe izintambo ze-aluminium ezivikela izintambo ze-PVC

| Indawo okuzisholo yona ye-conductor | Ukumelana okuphezulu kwe-conductor ku-20 ℃ | Ubukhulu be-xlpe insulation | Ubukhulu be-copper tape | Ubukhulu bezingubo zokulala ezikhishiwe | I-Dia ye-armor wire | Ubukhulu bomgodla wangaphandle | Appro.Ububanzi sebonke | Appro.Isisindo sekhebula |

| mm² | Ω/km | mm | mm | mm | mm | mm | mm | kg/km |

| 35 | 0.524 | 2.5 | 0.075 | 1.2 | 1.6 | 1.8 | 25.5 | 1020 |

| 50 | 0.387 | 2.5 | 0.075 | 1.2 | 1.6 | 1.8 | 26.6 | 1180 |

| 70 | 0.268 | 2.5 | 0.075 | 1.2 | 1.6 | 1.8 | 28.2 | 1440 |

| 95 | 0.193 | 2.5 | 0.075 | 1.2 | 1.6 | 1.9 | 30.3 | 1760 |

| 120 | 0.153 | 2.5 | 0.075 | 1.2 | 1.6 | 1.9 | 31.8 | 2050 |

| 150 | 0.124 | 2.5 | 0.075 | 1.2 | 1.6 | 2 | 33.4 | 2380 |

| 185 | 0.0991 | 2.5 | 0.075 | 1.2 | 2 | 2 | 35.8 | 2840 |

| 240 | 0.0754 | 2.6 | 0.075 | 1.2 | 2 | 2.1 | 38.7 | 3490 |

| 300 | 0.0601 | 2.8 | 0.075 | 1.2 | 2 | 2.2 | 41.3 | 4180 |

| 400 | 0.047 | 3 | 0.075 | 1.2 | 2 | 2.3 | 44.8 | 5160 |

| 500 | 0.0366 | 3.2 | 0.075 | 1.3 | 2.5 | 2.5 | 49.8 | 6490 |

| 630 | 0.0283 | 3.2 | 0.075 | 1.4 | 2.5 | 2.6 | 54 | 8020 |

3.8/6.6kV-Amakhora amathathu ekhondatha yethusi i-XLPE efakwe itheyiphu yethusi evalwe ngentambo yensimbi eyakhiwe ngensimbi enezintambo ezinemishele ye-PVC

| Indawo okuzisholo yona ye-conductor | Ukumelana okuphezulu kwe-conductor ku-20 ℃ | Ubukhulu be-xlpe insulation | Ubukhulu be-copper tape | Ubukhulu bezingubo zokulala ezikhishiwe | I-Dia ye-armor wire | Ubukhulu bomgodla wangaphandle | Appro.Ububanzi sebonke | Appro.Isisindo sekhebula |

| mm² | Ω/km | mm | mm | mm | mm | mm | mm | kg/km |

| 35 | 0.524 | 3.4 | 0.075 | 1.2 | 1.6 | 1.8 | 27.3 | 1130 |

| 50 | 0.387 | 3.4 | 0.075 | 1.2 | 1.6 | 1.8 | 28.4 | 1290 |

| 70 | 0.268 | 3.4 | 0.075 | 1.2 | 1.6 | 1.9 | 30.2 | 1560 |

| 95 | 0.193 | 3.4 | 0.075 | 1.2 | 1.6 | 1.9 | 32.1 | 1880 |

| 120 | 0.153 | 3.4 | 0.075 | 1.2 | 1.6 | 2 | 33.8 | 2190 |

| 150 | 0.124 | 3.4 | 0.075 | 1.2 | 2 | 2.1 | 36.2 | 2620 |

| 185 | 0.0991 | 3.4 | 0.075 | 1.2 | 2 | 2.1 | 37.8 | 3000 |

| 240 | 0.0754 | 3.4 | 0.075 | 1.2 | 2 | 2.2 | 40.5 | 3640 |

| 300 | 0.0601 | 3.4 | 0.075 | 1.2 | 2 | 2.2 | 42.5 | 4290 |

| 400 | 0.047 | 3.4 | 0.075 | 1.2 | 2 | 2.4 | 45.8 | 5270 |

| 500 | 0.0366 | 3.4 | 0.075 | 1.3 | 2.5 | 2.5 | 50.2 | 6550 |

| 630 | 0.0283 | 3.4 | 0.075 | 1.4 | 2.5 | 2.6 | 54.4 | 8020 |

Umkhiqizo Ongeziwe

Thumela I-imeyili

Thumela I-imeyili